Dust and Powder Flammability Testing

BS EN 13821 (withdrawn) / BS EN ISO IEC 80079-20-2 / ASTM E2019

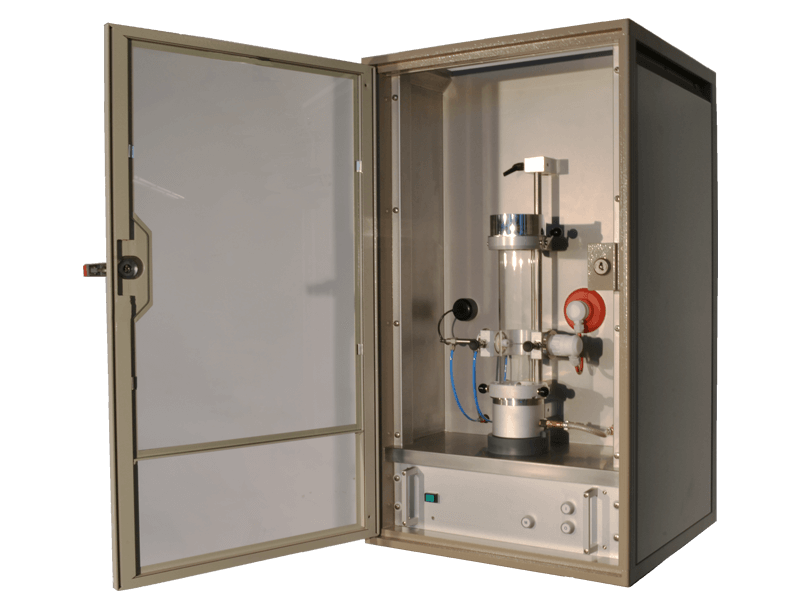

The MInimum Ignition Energy (MIE) test is conducted to determine the lowest spark energy that will ignite a powder when dispersed in air, as a dust cloud. A purely capacitive generated spark is used for assessment of electrostatic discharges (brush, spark, transitional / propagating brush discharges) incendivity. An inductive generated spark is selected for mechanical (friction, impact and grinding) or electrical (wire short, electrical contact) spark incendivity analysis.

Working through a range of powder concentrations, the material is dispersed into a 1.2L litre glass vessel using, dry compressed air. These momentarily suspended dust clouds are then exposed to sparks of known energy and duration. The energy is lowered, the powder concentration and time delay varied until the ‘MIE’ is established.

MIE data is typically used to define the minimum spark energy needed to ignite a dust cloud of the process material in the operating environment. It is one of three core tests where ‘Avoidance of Ignition Sources’ is the ‘Basis of Safety’ for the operation. This approach looks at testing of materials to determine how sensitive they are to specific ignition sources such as electrostatic discharges, mechanical & electrical sparks and hot surfaces. This Basis of Safety is often used when charging vessels from sacks, IBC’s or FIBC’s, pneumatic conveying, milling and tabletting operations to name a few. Many materials, that can create a flammable atmosphere, are found to be insensitive to ignition and therefore it is easy, practical and cost affective to ensure an ignition source capable of initiating a reaction is not present.

A sub-group of ‘Avoidance of Ignition Sources’ would be the electrostatic properties of products and materials being used in the process environment. This may vary from the electrostatic properties of the materials being processed, electrostatic properties of containers or transfer mediums and even Personal Protection Equipment (PPE) such as shoes and gloves, etc. This is particularly important where process materials are found to be very sensitive to ignition.

Related testing for Avoidance of Ignition Sources are Minimum Ignition Temperature (MIT), Layer Ignition Temperature (LIT) and Electrostatic testing.

Dust Combustibility (Group A/B)

Read More

Minimum Ignition Temperature (MIT)

Read More

Layer Ignition Temperature (LIT)

Read More

Minimum Explosive Concentration (MEC)

Read More

Burning Behaviour

Read More

Explosion Severity (Pmax, Kst)

Read More© 2024 Sigma-HSE (India) Pvt Ltd | Registered in India No. U93000DL2014PTC266010 | Designed By WebClixs